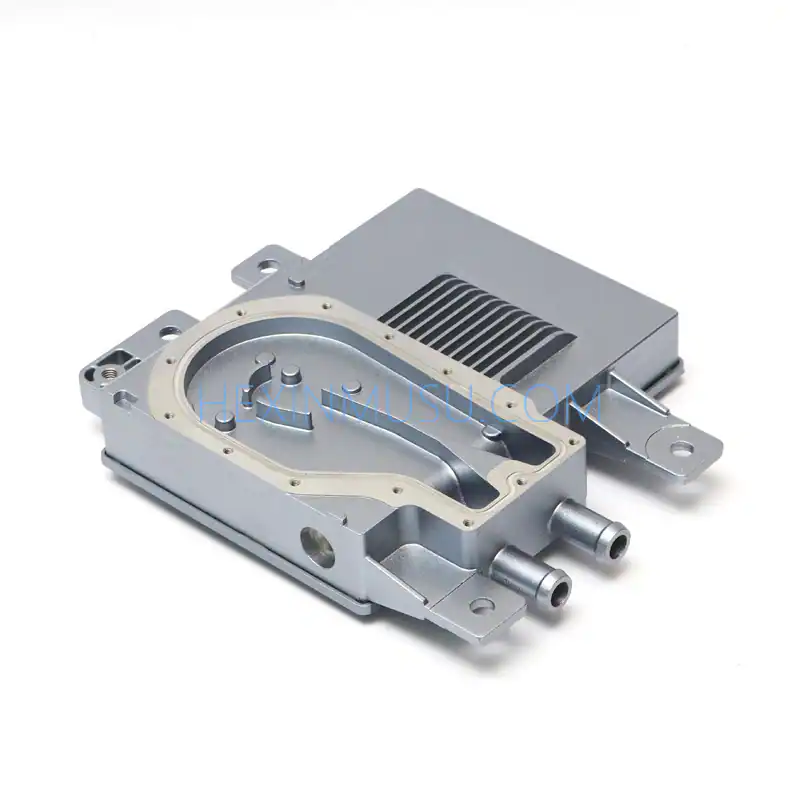

Die-cast aluminum oil seal housing specifically engineered for construction machinery and industrial transmission systems. Constructed from high-strength ADC12 aluminum alloy in a single-piece design, its lightweight structure (approx. XX grams) balances load-bearing capacity with heat dissipation performance, effectively addressing industry pain points such as oil seal overheating, aging, and leakage during prolonged operation.?The housing internally accommodates mainstream standard oil seals (e.g., TC, SC, NA series) and supports shaft diameters ranging from 20-120mm. Combined with multi-lip sealing and dust-proof design, it ensures long-lasting sealing performance even in harsh environments with dust or moisture.Both inner and outer surfaces undergo anodized treatment to form a wear-resistant, corrosion-resistant coating. Available in industrial colors like engineering gray and deep black, it supports flange mounting, threaded fastening, or embedded assembly. Adaptable to diverse layout requirements in construction machinery, gearboxes, pumps, valves, and other equipment, it offers a cost-effective solution for enhancing seal longevity and operational stability.

application scenario

Industrial Manufacturing

Gearbox Manufacturer: As the output-end seal housing, its temperature and pressure resistance characteristics are optimized for long-term operation in high-speed gearboxes. The aluminum casing facilitates heat dissipation, extending oil seal lifespan.

Pump and Valve Equipment Manufacturer: Flange-mounted design simplifies pipeline system assembly; anodized surfaces resist corrosion, suitable for chemical fluid environments.

Heavy machinery

Construction Machinery: Seals for the travel mechanisms of loaders/excavators, designed for a wide temperature range (-30°C to 150°C) to withstand outdoor temperature variations and high-frequency impacts.

Agricultural Machinery: Dust-proof structures block crop residue dust in the field, while lightweight designs reduce rotational inertia and enhance transmission efficiency.

After-sales Maintenance

Equipment Maintenance Station: Replaces traditional cast iron bases, reducing weight by 35% while enabling quick and easy disassembly and assembly, thereby lowering maintenance time costs.

Seal Distributor: Compatible with multiple oil seal specifications, offering rust-proof packaging and model labels for streamlined inventory management.

Customized services

- Supports custom non-standard aperture sizes and mounting hole positions to meet specialized equipment structural requirements.

- Laser engraving services for corporate logos and specification markings

- Can be combined with oil-resistant rubber bushings, anti-rotation pins, and other accessories to form a sealing kit.